Boeing to redesign 737 MAX section in wake of Alaska Air blowout, NTSB says

How did your country report this? Share your view in the comments.

Diverging Reports Breakdown

Boeing to redesign 737 MAX section in wake of Alaska Air blowout, NTSB says

Boeing and the FAA are to blame for a panel blowout on Alaska Airlines Flight 1282. NTSB: Boeing failed to provide “adequate training, guidance and oversight” FAA failed to ensure that Boeing addressed “repetitive and systemic nonconformance issues,” NTSB says. Boeing plans to begin building new 737 MAX airplanes with those changes in 2026, pending regulatory approval, the NTSB said. The FAA said it would “carefully evaluate” the safety board’s recommendations. to ensure Boeing is adhering to safety and quality expectations, the regulator said in a statement. The NTSB, which does not have regulatory or enforcement authority, is tasked with investigating accidents, determining what went wrong and issuing recommendations to reduce the chance of it happening again. report: Boeing will review the final report and recommendations “as we continue to implement improvements,’’ a Boeing spokesperson said. “We at Boeing regret this accident and continue to work on strengthening safety andquality across our operations’

On Jan. 5, 2024, a panel flew off a Boeing 737 MAX 9 roughly 15 minutes after taking off from Portland, Ore. While none of the 177 passengers and crew aboard were seriously injured, the mishap could easily have seen passengers ejected from the plane or, potentially, brought down the aircraft.

Early on, investigators with the National Transportation Safety Board determined that four bolts meant to hold the panel in place were missing. Boeing mechanics in Renton had removed the bolts and the panel for repairs but failed to reinstall the hardware properly, allowing the panel to slowly move up and out until it flew off the fuselage.

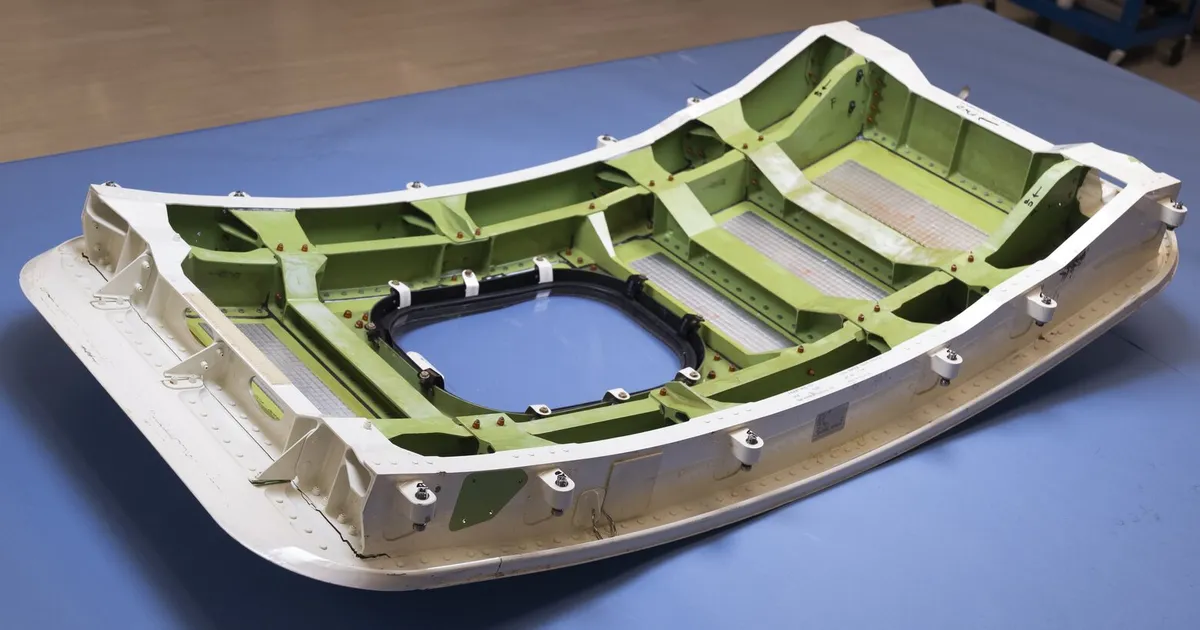

The anatomy of a door plug Four bolts on the sides of the door plug prevent it from moving upward. But in the accident on Alaska Airlines Flight 1282, the plug moved upward and fell out. Investigators believe the four bolts were removed during assembly at Boeing’s Renton factory and not reinstalled.

On Tuesday, the NTSB said Boeing had failed to provide “adequate training, guidance and oversight to ensure … manufacturing personnel could consistently and correctly comply” with some manufacturing processes.

“An accident like this does not happen because of an individual, or even a group of individuals,” NTSB chair Jennifer Homendy said at a hearing Tuesday. “An accident like this only happens when there are multiple system failures.”

Advertising

The NTSB, which does not have regulatory or enforcement authority, is tasked with investigating accidents, determining what went wrong and issuing recommendations to reduce the chance of it happening again.

The NTSB issued 19 recommendations to Boeing and the FAA, including new systems to track noncompliance and document employee training, and reconvene a third-party panel to conduct a review of Boeing’s safety culture. Those recommendations include design changes underway for new planes, and a directive from the FAA to require the changes on the current 737 MAX fleet flying today.

Boeing has finalized design changes meant to avoid another panel blowout like that which occurred on Alaska Airlines Flight 1282. The company plans to begin building new 737 MAX airplanes with those changes in 2026, pending regulatory approval, according to investigators from the NTSB.

In its report, the NTSB also found the FAA’s “ineffective compliance enforcement surveillance” contributed to the accident. The FAA failed to ensure that Boeing addressed “repetitive and systemic nonconformance issues.”

“The safety deficiencies that led to this accident should have been evident … to Boeing and to the FAA … and were therefore preventable,” Homendy said.

Boeing said it would review the final report and recommendations “as we continue to implement improvements.”

Advertising

“We at Boeing regret this accident and continue to work on strengthening safety and quality across our operations,” a spokesperson said.

The FAA said it would “carefully evaluate” the safety board’s recommendations issued Tuesday, adding that it will maintain increased oversight of Boeing to ensure the company is adhering to safety and quality expectations.

“The FAA has fundamentally changed how it oversees Boeing since the Alaska Airlines door-plug accident and we will continue this aggressive oversight to ensure Boeing fixes its systemic production-quality issues,” the regulator said in a statement.

Design changes

The panel that blew off Alaska Airlines Flight 1282, known as a door plug, fills a hole in the fuselage that some planes configured with high-density seating use as an emergency exit. For those that don’t, Boeing fits a plug into the space secured with four bolts, as well as 12 stop pads and fittings, which press together.

The door plug doesn’t need all four bolts to stay in place, NTSB investigators determined. It was designed with redundancy, a tenant of aviation that means if one system, part or process fails, another one fills that gap.

In this case, the door plug would have been able to stay on with just one of the two lower locking bolts or both upper locking bolts.

Advertising

Since the accident, Boeing and supplier Spirit AeroSystems have designed a second “retention device,” a hammer-shaped device that engages with the stop fittings to prevent upward movement. Mechanics must rotate that device into position to complete installation.

Boeing also added lanyards on the four bolts to permanently secure them in place and to act as a visual indication that they are installed.

The FAA still needs to certify these design changes before Boeing can start working them into their manufacturing line.

Among the NTSB’s recommendations, it suggested that the FAA issue an airworthiness directive to require Boeing “retrofit” its existing fleet of 737 MAX planes with door plugs to include these new design changes.

FAA oversight

As it has in the past, the NTSB raised concerns about how effectively Boeing’s regulator is performing its job.

In its investigation, the transportation safety board found that the FAA did not systematically keep track of “noncompliance issues,” or areas where Boeing failed to meet design or regulatory standards. Because the FAA did not have a system for tracking those deficiencies over time, it rarely accounted for those recurring issues when developing a quality plan for Boeing each fiscal year, the NTSB determined.

Sponsored

Those concerns have come up before, including in an October report from the Department of Transportation’s Inspector General, which found the FAA had not done enough to identify or address risk within Boeing’s factories.

Since the accident, the FAA has increased the number of inspectors in Boeing factories and has ramped up the prevalence of unannounced audits, meaning regulators will get a better sense of how things normally work at the factory, the NTSB said.

The FAA said Tuesday it meets weekly with Boeing to “review progress and any challenges it is facing.”

It said Boeing is making progress but reiterated that it would not raise a cap on 737 monthly production at the Renton factory “until we are confident the company can maintain safety and quality while making more aircraft.”

Boeing reached that threshold — 38 planes per month — in May. CEO Kelly Ortberg has said Boeing won’t ask the FAA to lift that cap until it has proved it is still meeting key performance indicators it developed to monitor quality and safety. Still, Ortberg hopes to start that conversation this year.

Outside the factory

In its final report, the NTSB identified other deficiencies and safety recommendations that extend beyond Boeing’s factories.

Advertising

It called on aircraft operators to implement a 25-hour cockpit voice recorder, in order to preserve the audio inside the cockpit for a longer period of time, assisting accident investigators in determining what was happening inside during a crisis. That requirement is now in place for new airplanes under the 2024 FAA Reauthorization Act but NTSB members asked airlines to voluntarily update their existing fleet.

It also pointed to a gap in training for flight attendants on how to use some oxygen systems, like portable oxygen bottles. One flight attendant on Flight 1282 had so much difficulty with one of those bottles that she had to use her ID badge to tear through the packaging.

The NTSB also called on the FAA to strengthen requirements for infants who are sitting in a caregiver’s lap, rather than strapped into a seat, and pointed out that the flight crew’s manual did not have instructions for helping unaccompanied minors if the cabin were to depressurize.

A game of Whac-A-Mole

In August 2024, six months after the door plug blowout, NTSB member Todd Inman said it felt like the industry was “playing a game of Whac-A-Mole,” with new safety issues popping up every 5 to 10 years.

On Tuesday, Inman said he still felt that way.

Six years ago, it was a new software system on Boeing’s 737 MAX that ultimately led to two plane crashes that killed a total of 346 people. Last year, it was manufacturing and supply chain constraints. This year, its air traffic control problems, driven in part by a fatal collision of an American Airlines regional plane and an Army helicopter.

“Every year, we’re talking about something else,” Inman said. “How do we get to a place where we get comfortable (that) the entire system is working for aviation safety for everyone?”

Advertising

The question was directed at NTSB investigator Sabrina Woods, who was fielding inquiries from members of the NTSB about the investigation and its findings.

Woods responded with what she described as an unpopular opinion. “I do not feel you can ever 100% get to zero,” Woods said. “There’s an inherent risk to what we have here.”

The goal instead is to find a way to manage the risk so if something does happen, it doesn’t result in tragedy.

“We’re no longer flying bi-wing wooden planes. Aircraft have gotten inherently more complicated,” Woods said. “There will always be something on the horizon.”